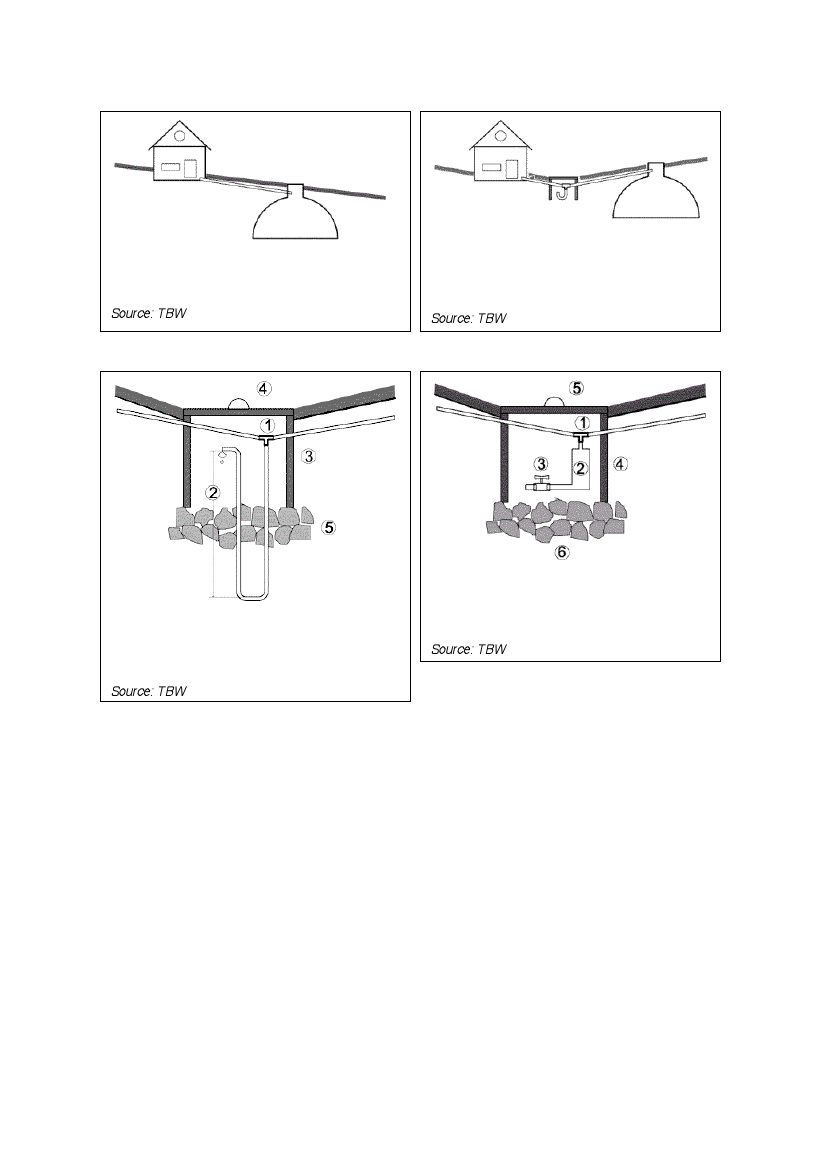

Figure 27: Piping system with straight slope

from kitchen to digester. No water trap required

as condensation water drains into the digester

Source: TBW

Figure 28: Wherever condensation water

cannot drain back into the digester, a water

trap becomes necessary

Source: TBW

Figure 29: Automatic water trap: (1) T-joint in the

piping system, (2) water column, equal to max.

gas pressure + 30% security, (3) solid brick or

concrete casing, (4) concrete lid, (5) drainage

Source: TBW

Figure 30: Manual water trap: (1) T-joint, (2)

buffer storage for condensated water, (3)

manual tap, (4) casing, (5) concrete lid, (6)

drainage

Source: TBW

Valves

To the extent possible, ball valves or cock valves suitable for gas installations should be

used as shutoff and isolating elements. The most reliable valves are chrome-plated ball

valves. Gate valves of the type normally used for water pipes are not suitable. Any water

valves exceptionally used must first be checked for gas-tightness. They have to be greased

regularly. A U-tube pressure gauge is quick and easy to make and can normally be expected

to meet the requirements of a biogas plant.

The main gas valve has to be installed close to the biogas digester. Sealed T-joints should

be connected before and after the main valve. With these T-joints it is possible to test the

digester and the piping system separately for their gas-tightness. Ball valves as shutoff

devices should be installed at all gas appliances. With shutoff valves, cleaning and

maintenance work can be carried out without closing the main gas valve.

50